Prepared by:

Mr. Ross Porter- Mayor of Smethport (Co-Chair)

Dr. Timothy G. Pierson- Penn State Extension (Co-Chair)

Mr. David Jordan- Penn State SBDC (Business Analyst)

And the SWBDP- Technical Committee

VERSION: June 7, 2012-2

i. Acknowledgements/Appreciation:

There have been many persons responsible for the thoroughness of the exploration/investigation into the Smethport Woody Biomass Demonstration Project (SWBDP) initiated by the Smethport Borough Council in 2008. It is important to acknowledge these individuals who provided leadership, professional expertise and time toward the success of this summary report.

The Smethport Woody Biomass Demonstration Project Leadership Team was made up of Smethport Borough leaders, McKean County leaders, Penn State faculty, DCNR- Bureau of Forestry leaders, USFS leaders, Local/State/Federal Political legislators and leaders, Forest/Wood Industry leaders, Forest Community leaders, and other stakeholders. This leadership team was responsible for developing the original thrust, mission, goals and objectives, and direction for the SWBDP. This team of individuals is listed below.

Smethport Woody Biomass Project Leadership Team Members:

Project Co-Chair: Ross Porter-Mayor, Borough of Smethport

Project Co-Chair: Timothy G. Pierson-Penn State University Extension

Lew McCreery-USDA-US Forest Service, NE US Biomass Coordinator

Paul Roth-PA-DCNR-Bureau of Forestry

Mike Palko- DCNR- Bureau of Forestry

Meredith Hill-PA DCNR-Conservation and Recreation

Charles Ray-Penn State University, School of Forest Resources

Ed Johnstonbaugh- Penn State University Extension

Don Tanner-Penn State University Extension

Robert Veilleux-Penn State University Extension

Tom Wilson- Penn State University Extension

Joseph DeMott-McKean County Commissioner

Al Pingie-McKean County Commissioner

Judy Church-McKean County Commissioner

Debbie Lunden-McKean County Planning Commission

Ray McMahon-McKean County Director of Economic Development

Linda Devlin-McKean County Tourist Promotion Agency

Gregory Rounsville-Smethport Borough Council President

Josh Costa-Smethport Borough Councilmen

Paul Raymond-Smethport Borough Councilmen

James Herzog-Smethport Board of Trade

Sean O’Day-Smethport Board of Trade

Terry Palmer–Smethport Borough Efficiency Committee

Jamie Pierotti–Smethport Board of Trade

Nathan Muller-Smethport Board of Trade/ Borough Web Master

Jovanna Porter-Smethport Borough Planning Commission

George Romanowski- Smethport Area School District Superintendent of Schools

Harold (Sandy) Wolfinger-Forester & Smethport Forest Landowner

Lois DeMarco- USFS- Allegheny National Forest Supervisor’s Office

Gerald Jones- American Municipal Power- Ohio

Marty Causer – State Congressman

Kyle Hannon- Senator Robert Casey’s Office

State Senator Scarnati’s Office

Howard Brush-PA-Governor’s Office

Deborah Pontzer-Congressmen Peterson and Thompson’s Office

Matt Murusiak-North Central Regional Planning and Development

Don Masisak- North Central Regional Planning and Development

Jack Rae- Manager/Engineer- Gannet/Fleming Engineering Inc.

Greg Roth- Penn State University- Renewable and Alternative Energy

The Smethport Woody Biomass Forest Sustainability Leadership Team was charged with identifying the issues and problems associated with utilizing woody biomass for energy (including the SWBDP) and providing recommendations to insure the sustainable utilization of the forest resource. This team was made up of leaders from across the forest community and included industry, timber harvesters, forest scientific researchers, forest and wildlife managers, public and private forest landowners and other stakeholders. This team provided the SWBDP with an understanding of forest sustainability issues associated with the utilization of locally harvested woody biomass as a CHP feedstock. The team also provided recommendations for future sustainable woody biomass utilization.

This team included the following individuals:

Paul Roth- DCNR Bureau of Forestry (Co-Chair)

Timothy G. Pierson- Penn State Cooperative Extension (Co-Chair)

Susan Stout- Project Leader- USFS: Northern Research Station

James Finley- Penn State University- School of Forest Resources

Larry Schultz- President, North Central Forest Landowners Association

Chuck Ray- Penn State University- School of Forest Resources

Lois DeMarco- USFS- Allegheny National Forest

Dan Evans- Forester- Domtar Paper Company

Luke Dillinger- Forester- Domtar Paper Company

Sue Swanson-McKean County Conservation District

Dylan Jenkins- The Nature Conservancy

Brad Nelson- Wildlife Biologist- Allegheny National Forest

Howard Wurzbacher- Forester- Pennsylvania Game Commission

Jeff Kochel- Forester Manager- Forest Investment Associates

John Lavavasseur- Forester- Hancock Forest Management

Nancy McCloskey- Forester- Forecon Inc.

Sandy Thompson- Manager- Mckean County Conservation District

Gus Christman- Logging Contractor

Tim Christman- Logging Contractor

Martin Melville- Logging Contractor

Lew McCreery, USFS- Biomass Coordinator

Ken Manno- Program Director- Sustainable Forestry Initiative of PA

Blaine Puller- Forester- Kane Hardwood

Ned Karger- Forester- Kane Hardwood

The SWBDP Technical Sub-Committee must be acknowledged for sharing their valuable time and expertise to insure that the SWBDP had a sound feasibility and engineering planning study, and business planning summary. This included the evaluation of various very technical CHP systems. This team of experts completed much of the work associated with grant writing, equipment/system engineering evaluation, feasibility study completion, engineering planning and business planning for the Smethport Woody Biomass Demonstration Project.

The committee leadership team members included:

Ross Porter, Tim Pierson, Gerald Jones, Chuck Ray, Terry Palmer, Paul Roth, Mike Palko, Jack Rae, Lew McCreery, Ed Johnstonbaugh, Jovanna Porter, David Jordan, Jeff Tanner, Nathan Muller. New committee are members:

Mike Palko- Biomass Energy Specialist-DCNR- Bureau of Forestry

David Jordan- Business Consultant- Small Business Development Center (Penn State University)

Wulf Hohmann- Project Manager/Engineer- Lahmeyer International (Energy Division)

Darek Letkiewicz – Vice President/Engineer- O’Brien & Gere Engineering

We must acknowledge other persons that played important roles in providing necessary components for the SWBDP.

David Taylor- Smethport/Penn State Engineering Student- Smethport Borough Heat Study

Cheryl O’Rourke– Information to Borough Electric Customers

Ken Bush- McKean County Buildings Study

Claudia Caminite- German Interpreter and Interviewer

John Karakesh- Forester/Biomass Engineering Technology Consultant

Chris Swanson- Physics Teacher Smethport High School

Allen Jackson- Lakeview Retirement Community

Bob Larson- First Renewable Energy

Jim McNamara- Nexterra Systems Corp.

Timothy Keister- ProChemTech International Inc.

Michael Kocjancic- President/Owner-New Growth Resources Inc.

Geoffrey Bristow- Manager- PA DEP

Erin Wells- Community Consultant- PA DEP

John Frailey- Vice President Engineering- AFS Energy Systems

Amy Keth- Business Consultant- Small Business Development Center (Clarion University)

The following organizations played an instrumental role by providing expertise, knowledge, and valuable time to assemble the knowledge needed for educated development of the Smethport Woody Biomass Demonstration Project:

Pennsylvania DCNR – Bureau of Forestry

USFS- Wood Education and Resource Center

USFS- Allegheny National Forest

USFS- Northern Research Station

American Municipal Power

Smethport Borough Council, Planning Commission, Board of Trade, Water Authority

Penn State Cooperative Extension

Penn State School of Forest Resources

Penn State Small Business Development Center- Clean Technology Resource Center

Penn State Biomass Energy Center

Pennsylvania Department of Environmental Protection

Pennsylvania Department of Community and Economic Development

North Central Regional Planning and Development

The Nature Conservancy

North Central Forest Landowners Association Inc.

McKean County Commissioners Office, Planning Office, Conservation District

O’brien and Gere Engineering

Lahmeyer International (Energy Division)

Seeger Engineering (Germany)

GEF Engineering (Germany)

First Energy Corp.

Advanced Recycling Corp.

The McFarren Group

AFS Energy Systems

ProChemTech International Inc.

First Renewable Energy

Sustainable Forestry Initiative of PA

New Growth Resources Inc.

We also recognize and are very appreciative of the following foundations and organizations that provided funding to complete a thorough feasibility, engineering and business planning study for the Smethport Woody Biomass Demonstration Project.

Community Foundation for the Alleghenies

Richard King Mellon Foundation

Wood Education and Resource Center

Pennsylvania Department of Community and Economic Development

Table of Contents

i. Acknowledgements/Appreciation

I. Background

II. Project Goals

III. Development of a Feasibility Study

IV. Feasibility Study Findings

V. Estimated Project Cost Summary

VII. Impact of Renewable Energy Credits

VIII. 2011 Project Redirect

IX. Conclusions

X. Appendix

I. Background

Smethport, Pennsylvania is in McKean County, one of the state’s most heavily forested counties, where the Borough of Smethport, population 1,684, lies within millions of acres of federal, state, and privately owned forests. It’s a small town with a history of creativity, gas and oil development and a past wood/lumber industry. The toy industry, developed more than 100 years ago, is still going strong while the wood industry languished in the early 1930’s. However, gas development is resurging. Smethport is the only municipality in the entire 12 county Pennsylvania Wilds Region to supply electricity to residents of the Borough and surrounding region through a Borough owned electric utility company. Furthermore, Smethport is located in the center of the PA Wild’s vast wood basket, making plentiful woody biomass feedstocks sustainably available within the immediate region, including the 510,000 acre Allegheny National Forest and huge tracts of private (industrial and non-industrial) and state forestlands.

Since the 1920s, the borough has owned and operated its own electric company. To this day, it remains unique in the twelve-county “Pennsylvania Wilds” region as the only municipality that runs its own power company. This utility services its own transmission lines and purchases electricity from outside generators through a cooperative agreement with American Municipal Power (AMP). It does not own or operate its own electricity generation capability.

The town has a major water infrastructure problem as do many of our communities in Pennsylvania. The borough’s 100-year-old water system is in desperate need of replacement. Old failing piping systems run underground throughout the community and are a constant source of major leaks and water pressure problems. The price tag to rebuild the system was estimated in 2008 at $20 million based on a thorough feasibility study completed by Gannet- Fleming Engineering. Unfortunately for a community of fewer than 1,700 people this expense is estimated at a figure that is close to $12,000 per person.

The issue of the replacement of the water infrastructure; the continued rise in oil and fossil fuel prices and an opportunity to develop a European style energy system rekindled an interest in a 1980 plan to utilize woody biomass from the surrounding forest. Back then, the McKean County Industrial Development Council did a feasibility study, looking at the construction of a fifty-megawatt power plant generating electricity through the burning of woody biomass harvested from the area. This study indicated the technical and financial feasibility of a generation project. This project was not implemented by the County.

Fast forward almost 30 years and the Borough of Smethport has been investigating and studying the possibility of constructing a woody biomass fueled combined heat and power (CHP) facility which could be designed to provide a renewable energy heating solution to its residents and generate electricity which could be used locally and sold to the “grid”. This exploration revisited the 1980 plan and its local benefits for the Community, County and Region. The project outlined a plan District Heating which would deliver heat produced by the CHP facility to the County offices, School District, businesses and residents. The installation of the district heat piping would provide an opportunity for replacing the failing water infrastructure and the electric power generated would add to the Borough Utility an additional capital source. This opportunity was first presented to the Smethport Borough Council for their consideration by Mayor Ross Porter and members of the Austrian Energy Delegation from Penn State University, DCNR-Bureau of Forestry and the US Forest Service.

Biomass Utilization in Güssing, Austria

In June 2008, a 20-member U.S. delegation visited biomass facilities in Austria, including Dr. Timothy Pierson, McKean County Extension Forester and Educator, Dr. Charles Ray, Associate Professor in Penn State’s School of Forestry, Paul Roth, Inventory and Analysis, Section Chief from DCNR Bureau of Forestry and Lew McCreery- Biomass Coordinator with the U.S. Forest Service. The rural town of Güssing operates a biomass gasification system that has been serving 4,000 residents for 15 years.

Dr. Pierson meet with Mayor Ross Porter to discuss the possibility of a CHP in Smethport fueled with woody biomass from local forests. Together the Mayor and members of the delegation provided the Smethport Borough Council with a briefing on July 14, 2008, showing slides of the trip and explaining the process used to convert wood chips into heat and electricity. From this point until today, Mayor Ross Porter and Dr. Timothy Pierson served as Co-Chairs for the Smethport Woody Biomass Demonstration Project. Dr. Pierson noted that Güssing, located in southern Austria, looks and feels very much like Smethport, but that Smethport has far more timber and water resources to draw upon for this type of energy production.

Dr. Pierson also noted that 600 to 1,000 people a week now visit Güssing just to tour their energy biomass facilities. Obviously, Eco-energy tourism might also be an opportunity since Smethport would be the first whole community in the United States that would be energy independent using locally available woody biomass The whole facility takes up a plot of land about the size of a football field. The plant burns wood chips cleanly at approximately 93% energy efficiency and therefore would be a good fit for the Borough.

The situation was much different in Güssing before renewable energy independence and appeared very similar to small North Central Pennsylvania communities like Smethport. “The town was losing jobs, losing its agricultural base, the economy was stagnant, and the young people were leaving. Now, the town has a thriving tourist trade, an R&D center, a business incubator, and a hotel,” Pierson said.

Upon receiving the overwhelming approval of the Smethport Borough Council to explore a Woody Biomass fueled CHP project, Mayor Porter and Tim Pierson formed the Smethport Woody Biomass Demonstration Project Leadership Team (SWBDPLT). The purpose of this Leadership Team was to evaluate the feasibility of a CHP facility in Smethport and to articulate its vision for this project. The vision of the leadership team as developed in the fall of 2008 is described below.

It is the vision of the SWBDPLT to facilitate the research and development of a woody biomass, combined heat and power (CHP), demonstration pilot plant near or within the Borough of Smethport, which will provide carbon neutral, sustainable, locally produced, renewable electric power and auxiliary district heat to Borough customers as a possible joint venture between public and private funding sources and ownerships.

The pilot demonstration project would serve as a model to other communities desiring to achieve local energy independence by replacing non-renewable fossil fuel feedstocks with sustainable woody biomass feedstocks as a fuel source.

II. Project Goals

During the fall of 2008, the Leadership Team also developed a set of goals for the proposed biomass CHP facility. These goals are summarized below.

● To build a CHP facility that demonstrates the latest state-of-the art, carbon neutral renewal woody biomass technology for producing heat and power as a joint venture between public and private funding sources and ownership

● To capture and re-circulate energy dollars within the regional and local economies (2006 Smethport Borough electric expenditure under Select Energy – 16.3 MW @ $1,087,147.72)

● To supply Smethport Borough electric customers including: the Smethport Area School District, municipal, educational, commercial and residential with cost-effective woody biomass CHP power

● To establish a positive business & industrial environment with comparatively inexpensive cost effective heat & energy resources

● To coordinate funding streams for the replacement and installation of the Borough’s antiquated and failing water pipe-line infrastructure while simultaneously installing new hot water lines used to deliver district heat

● To sustainably utilize low-value wood from private and public (ANF and State Forest) through timber stand improvement and salvage operations

● To establish Smethport as an energy independent borough (Bio-Energy Borough) with a locally controlled, affordable, sustainable, energy supply lasting into the foreseeable future and beyond

● To produce an economic engine for green energy related businesses, services, and industry research and development

● To provide an educated workforce for woody biomass technologies

● To foster opportunities for eco-energy tourism in Smethport and the surrounding region, including the development of a tourism infrastructure

● To utilize the Renewal Portfolio Standards legislation to benefit the Smethport Borough

● To develop innovative partnerships between federal, state, and local agencies, institutions, and organizations

III. Development of a Feasibility Study

The first phase of the Smethport CHP project involved conducting a feasibility study, engineering/construction plan and developing a business plan. In March 2009, a Request for Qualifications (RFQs) was sent to 65 engineering firms located both in the U.S. and Europe identified by the U.S. Forest Service and additional organizations.. Twelve engineering firms responded with applications for the Smethport project.

Applicants submitted a Statement of Qualifications (SOQ), which were evaluated according to a weighted matrix system. The first four items on the matrix were “must haves”. Firms that lacked any of these items were automatically eliminated from further consideration.

In early August 2009, after a thorough evaluation by a select panel representing the 30-member Smethport Woody Biomass Leadership Team (SWBLT), the German engineering firm, Lahmeyer International emerged as the most qualified.

The selection of Lahmeyer followed a $50,000 award from the Richard King Mellon Foundation and a $25,000 award from the Community Foundation for the Alleghenies. Additional feasibility study funds were awarded by the Wood Education and Resource Center, US Forest Service, U.S. Department of Agriculture in the amount of $75,000.

Prior to engaging with Lahmeyer, the SWBLT completed much of the pre-feasibility work. A thorough database of Borough customer heat loads for the 900 buildings in Smethport was prepared to assist Lahmeyer in its planning. A heat load survey included with electric bills yielded a 68 % response rate and was followed up by David Taylor from Smethport.

The feasibility study was to include an assessment of the opportunities, as well as recommendations to deploy a Combined Heat and Power (CHP) plant, fueled by woody biomass feedstock to supply the power and heating needs of the Borough.

The Smethport Woody Biomass Demonstration Project specifically called for European expertise in wood-fired CHP plants and district heating systems. Lahmeyer International, as an independent engineering consultant formed a team of specialized consulting and engineering companies, , teaming up with GEF Ingenieur AG and Seeger Engineering AG, two other established companies from Germany. Finally, the US Engineering Firm O’Brien & Gere was added to the team and provided consulting and technical assistance along with Gannet Flemming Engineering in the development of the feasibility plan.

IV. Feasibility Study Findings

The conceptual design of the wood fueled CHP-plant was based on the outcomes of the Heat Demand Evaluation and of the Distribution System Investigation.

Three different alternatives for a wood fueled CHP plant as base load were elaborated for the case under consideration and were compared technically and financially. For all three alternatives hot water boilers fired with fossil fuels were designed to provide peak load and redundancy.

Regarding economics the best solution with the lowest specific heat generation costs for the case under consideration was identified as “Alternative 3” of the three options developed by Lahmeyer. According to the Lahmeyer Report – “From a technical point of view, all three alternatives represented reliable technologies that already have proven their suitability in practical operation for years (ORC) or even decades (steam turbines). But alternative 3 was the only concept that allows for increased power generation when heat demand is lower than estimated, e.g. in the initial stage of the project (worst case). This gave Alternative 3 a clear advantage over the other two alternatives.

Alternative 3 was a biomass CHP plant with steam boiler system and an extraction condensing type steam turbine – additional details are:

● Combustion heat performance: 75.7 MM BTU/hr (22.2 MW)

● Max. electrical output: 5.4 MW

● Max thermal output: 34.2 M BTU/hr (10.0 MW)

V. Estimated Project Cost Summary – from Lahmeyer Report

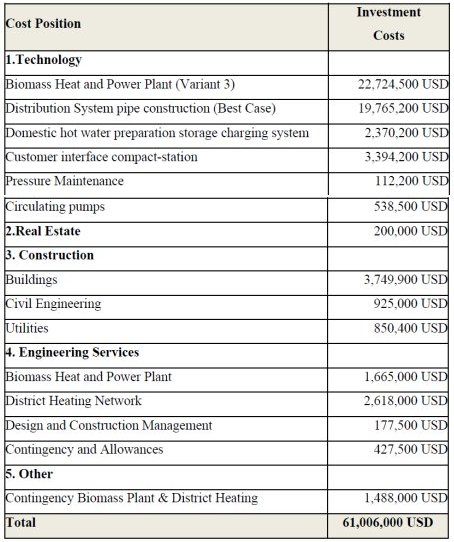

The capital costs for the different parts of the project are shown in Table 1.

Table 1: Project Capital Cost

VI. Financial Assumptions

The financial assumptions used by Lahmeyer to develop the feasibility study focused on principally three variables:

● The availability of a U.S. Federal Government-Department of Treasury grant that would be available to the construction engineering firm and the community of Smethport to fund 30% of the total project cost.

● Cost of wood chips

● Availability of Feed In tariffs – Renewable Energy Credits (REC’s)

● Virtually a 100% “take rate” – by definition – this would suggest that all current residential and commercial/industrial properties would convert from their current heat deliver service to the “to be constructed” Biomass CHP facility.

The initial estimation regarding subsidies is a 30% cash grant for the biomass CHP plant, which equals 9.45 M USD. There are no subsidies considered for the district heating net in the initial estimation.

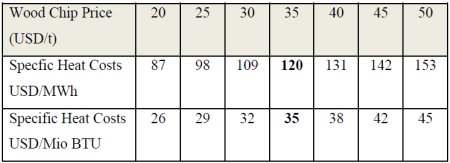

The Tables below illustrates a sensitivity analysis that was performed by Lahmeyer as they consider both the pricing for wood chips and availability of Feed In Tariffs (REC’s)

Wood Chip Price

The initial price for wood chips of 35 USD/t (including transportation) was varied from 20 USD/t to 50 USD/t in steps of 5 USD/t.

Table 2: Sensitivity Analyses Specific Heat Costs for different Wood Chip Prices

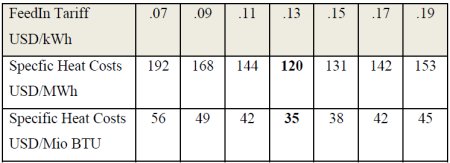

Power Feed-In Tariff

The initial power feed-in tariff of 0.13 USD/kWh (including rights on RECs) was

varied from 0.07 USD/kWh to 0.19 USD/kWh in steps of 2 ct/kWh.

Table 3 Sensitivity Analyses Specific Heat Costs for different Feed-In Tariffs

VII. Impact of Renewable Energy Credits

The Tier I Alternative Energy Credit (AEC) market in Pennsylvania provides financial support to renewable energy project development and operation. The market for this class of AEC has been slow to develop but continues on a slow steady climb in price. As the energy market recovers the AEC price should track rising demand for electricity. Annually the demand for these credits that must be purchased by regulated Electric Distribution Companies and Competitive Generation Providers also increases through the year 2021. This will also drive prices for AECs up. The current market has increased from $0.85 per AEC to $2.30 per AEC over the preceding 6 month period. It is anticipated that prices for AECs will continue to increase at the current rate of increase to a level in the range of $25 to $30 per AEC by 2021.

VIII. 2011 Project Redirect

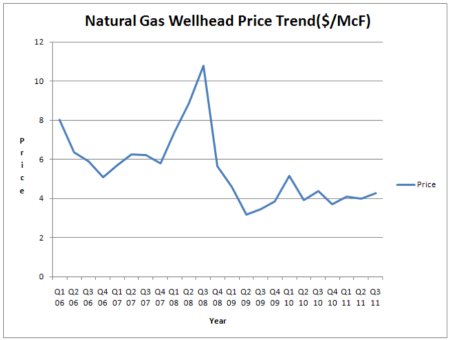

Over the course of the last three years two major market factors have caused the Leadership Team to reconsider the future direction of this project. These factors are – the significantly lower costs for natural gas and the dramatic reduction in the market value of renewable energy credits (REC’s).

Lower cost of Natural Gas: Originally conceived as a nearly borough-wide, woody biomass, district heating solution for the community of Smethport, this project was adversely impacted by the tremendous influx of natural gas development in the Marcellus Shale region. This has contributed to a significant drop in the end-user cost of natural gas, (June, 2008/ $12.685 MMBTU and in September 2011/ $3.896MMBTU) thereby dramatically reducing the yearly heating costs per household. This radically changed the economic feasibility of the project since nearly 95 % of Smethport residents use natural gas for home heating. The reduced cost of natural gas created a less appealing choice for residential customers.

This graph shows the trend in U.S natural gas prices from January 2006 through September 2011.

During February, 2010, based on the changing dynamics of energy prices, American Municipal Power expressed concerns regarding the feasibility of this project and consequently, dramatically reduced their future involvement in this project.

Renewable Energy Credit Prices: The Pennsylvania Alternative Energy Portfolio Standard (AEPS) requires that an annually increasing percentage of electricity sold to retail customers in Pennsylvania is from alternative energy sources. The program requires that retail energy suppliers utilize Alternative Energy Credits (AECs) for demonstrating compliance with the standard. An AEC is created each time a qualified alternative energy facility produces 1000 kWh of electricity. The AEC is then sold or traded separately from the power. This makes it easy for individuals and businesses to finance and invest in clean, emission free alternative energy. However, a decline in the tradeable value of these credits reduces the potential profit gains from developing renewable energy projects.

As a result, the Leadership Team in early 2011 decided that the best way to move forward with this project was to reduce the project size and scope. The focus needed to shift to a CHP facility that might only serve the McKean County complex, the Smethport Area School District and several additional privately owned commercial properties located in close proximity to the proposed facility. It may be prudent to recommend two separate facilities; one to service the school buildings and a second facility to serve the needs of the county complex. Depending on future market and economic conditions the project would have the ability to be expanded.

1. Budgetary Costs for this project

Paul Lewandowski, a representative from AFS Energy Systems, presented a proposal for a 5MW plant. The total budget estimated costs for this project are $15,051,000.

Robert Larson, an engineer with First Renewable Energy, presented a proposal for a 5MW Organic Rankin Cycle (ORC) CHP plant. The total budget estimated for this facility was.

2. Siting the facility

During this project redirect it was determined the ideal location for the CHP facility would be in West Smethport within close proximity to the McKean County complex; however, the main electricity substation is located on the eastern side of the community. First Energy (FE) representatives discussed the options for siting the facility and the corresponding costs that might be associated with each option. The First Energy team gave rough estimates of the interconnection costs for this project at $1,500,000 – obviously this number needs to be confirmed with further data and analysis. This issue is addressed later in this document

3. Project Scope

If this project shifts from a Smethport Borough project to one that is driven by the County and its desire to develop an alternative heating solution, there must be some discussion with the McKean County Commissioners to present a new plan to this group and understand the process the project might have to follow in order to receive approval (e.g. referendum or ballot requirements and the County’s willingness and ability to consider some level of municipal financing on this project).

4. First Energy’s participation in this project

First Energy which provides electric transmission services to the entire region surrounding the Smethport Electric company service area, meet with the SWBDP Technical Committee to discuss transmission of power generated to the grid and requirements for such services. First Energy may also have an interest in supporting and partnering with Smethport Electric.

Primarily due to change economic conditions and First Energy’s ability to buy needed capacity from the lowest cost provider, First Energy expressed little interest in either of the following at the present time:

• Some level of investment in the interconnection expense in exchange for some type of “enhanced” agreement.

• Owning/operating the Smethport CHP facility either solely or in partnership with Smethport or McKean County.

They did however propose a simple power purchase agreement with Smethport to purchase excess electricity capacity at $.06 per kwhr. One factor impacting First Energy’s participation in the project is the dramatic decline in REC values during the course of the last several years. First Energy was also interested in the community development, carbon-neutral components and job creation aspects of the project. This is worth exploring in the future.

Issues:

● Electrical grid interconnection expense – Engineering Study

While the First Energy team did indicate that the interconnection expense could approach $1.5 million ($200,000 – $250,000 per mile for a 34KV line), there is a need to conduct an engineering feasibility study with First Energy to determine the actual costs for this piece of the project. The First Energy engineering analysis will cost $20,000. It is unclear how these costs would be financed.

● Return on Investment/Payback Model

A financial model will need to be developed that outlines:

○ Project Cost estimates

○ Financing Options

○ Payback/ROI based upon current heat demand (in the County buildings), as well as assumptions about fuel sources/costs over some period of time (3-5 years) and the sale of electricity and REC’s.

IX. Conclusions

The Leadership team acknowledged a few critical factors that would make them revisit this project. These factors are discussed below

Natural Gas Pricing

The price of natural gas is a macroeconomic issue that is impacted by its supply and demand, amongst other factors. However, it is one critical variable that placed significant economic pressure on the Smethport Woody Biomass Project. Due to the sustained low prices for natural gas over the last few years, the woody biomass project is not price competitive. Though many industry experts believe that natural gas prices will begin rising within the next several years, a number of events must take place to ensure this prediction is correct. According to the financial models, a natural gas price above $6/Mcf will be favorable for this project

One key influencing factor could be a migration in the automobile industry from gasoline combustion engines to vehicles that are powered by compressed natural gas (CNG). Pike Research predicts that Annual worldwide sales of natural gas vehicles will jump 68 percent to 3.2 million vehicles in 2016 from 1.9 million in 2010. Given an overall worldwide shift away from fossil fuel towards natural gas and alternative energy the net result will be an increase in the price for natural gas.

Renewable Energy Credits

These programs are typically administered and monitored by State governments. Currently, Pennsylvania does not have a comprehensive and innovation alternative energy plan. The lack of such a plan will continue to place projects such as the one conceived for Smethport at a significant disadvantage. REC prices have been relatively low for the last few years. As stated earlier, this project would benefit from high REC prices. Favorable prices would exceed $0.15/kWh.

Grant Funding

The availability of federal and state grants to help fund this project will have a huge impact on the project’s viability. It was decided that a minimum of about $500,000 in grant funds will be needed to fund each separate facility – school district and county buildings.

Federal U.S. Energy Policy

The U.S. must step up and take the lead in the development of an aggressive plan to embrace emerging alternative energy solutions.

Over the course of the last decade this issue of energy sourcing has become one of a national security concern. The United States still continues to purchase over 50% of its oil requirements from countries many of whom do not have a favorable attitude towards the U.S.

Another key factor to consider in the development of an alternative energy policy is the fact that fossil fuels by definition a finite energy source. With the emergence of China, India and numerous other Asian countries as dominant economic regions, the worldwide demand for energy will only continue to accelerate at exponential rates.

Appendix

Smethport Woody Biomass Demonstration Project

Forest Sustainability Leadership Team

Issues and Recommendations

Smethport Woody Biomass Demonstration Project

Woody Biomass Forest Sustainability Leadership Team

April 16, 2009, 10:30 – 2:30 PM

Issues and Recommendations

I. Forest Sustainability Issues (associated with harvesting woody biomass for energy)

A. Sustainability:

(#1) Seven Sustainability Questions still pertain

• Deer

• Advanced regeneration

• Seed source

• Interfering plants

• Changes in stand quality

• Changes in diameter distribution

• Species composition

(#2) Benefits to wildlife

• Wildlife habitat

• Game management

(#3) Being a Component of keeping forests as forests

(#4) Good inventory information (address sustained yield)

• Water quality/erosion control

• Forest resource- biomass retention/coarse woody debris

• Living Laboratory

• Need for research

• Need for monitoring

• Soil impacts:

• Soil science

• Nutrient cycling

• Compaction

• Contamination

ANF Forest Management (supply access)

Is sustainable forest management a prerequisite for furnishing?

• Linear or circular?

• Blended proportions?

• Scaling the region?

• Chain of custody?

• Species of concern (PNDI) (1)

• Ecosystem services (Carbon)

• Invasive species

• Sustains the forest

• Looking at sustainability through the lens of a community and its resources

• Ash use and fertilization

• Ash use-classification

• Product sorting

• Harvesting future growing stock

Public Relations:

• Proactive delivery of benefits of good forestry/stewardship

• Societal Values: (paints a win/win situation)

• Public education

• Demonstration areas- educate others

• Logging Contractor education

• Landowner education

• Developing a public relations strategy for a sustainable feedstock

• Here’s how we are addressing your concerns

• Social license

• Integrity

• Transparency

Energy:

• Smethport sustains it’s future

• Energy Independence- local sources means local control (9)

• Competition for supply (8)

• Benefits to the local residents and resources (6)

• Economic development from woody biomass utilization (4)

• Sustainable energy production (4)

• Federal AEPS (2)

• Seasonal harvesting (1)

• Ownership cooperative- Benefits to all participants (1)

• Storage of fuel supply: (on-site/supplier) (1)

• Fuel contracts- Sliding rate adjustment (1)

• Contractor availability (infrastructure) (1)

• Location of plant

• Noise

• Air quality

• Environment

• transportation

• REC reimbursement

Recommendations:

• Classification of feedstock criterion – types of usable chips/residue

• Evaluate outcomes on a social value and resource value from a scientific basis

• Utilize DCNR-“Guidance on Harvesting Woody Biomass for Energy in Pennsylvania” by incorporating the existing Best Management Practices (BMP’s)

• Develop a LUW (Low Use Wood) TUSAF (Timber Utilization Stand Assessment Form) specifically for woody biomass

• Develop a formal outreach strategy for the general public, public/private forest landowners and managers and loggers regarding the sustainable harvest of woody biomass.

• How much is the community actually willing to invest (cost of the feedstock) in insuring use of sustainable practices?

• Begin considering how eco-energy tourism blends into this project and development potential demonstration areas.

• Develop regional by forest type specific (Down Woody Debris/Coarse Woody Debris) and nutrient standards/thresholds.

• Work through feedstock supply and market access based on sustainability criterion (price premium for certified material).